Ventajas de los sensores de posición de múltiples vueltas con encendido de energía real:

Los sensores de posición de múltiples vueltas con encendido de energía real revolucionan el campo de la detección de posición al ofrecer capacidades y beneficios sin igual. Estos sensores avanzados proporcionan mediciones precisas de posición incluso después de interrupciones de energía o reinicios del sistema, eliminando la necesidad de recalibración o inicialización. Con un consumo de energía nulo para mantener el seguimiento de la posición, ofrecen importantes ahorros energéticos y son especialmente adecuados para aplicaciones alimentadas por batería.

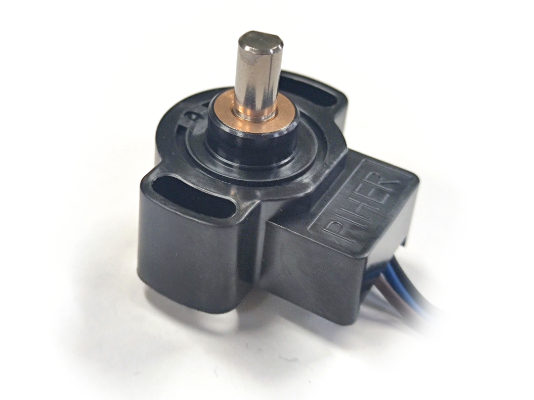

A diferencia de los sensores de posición tradicionales, los sensores de posición de múltiples vueltas con encendido de energía real ofrecen capacidad de múltiples vueltas, lo que permite una medición precisa a lo largo de múltiples rotaciones sin comprometer la precisión. Piher ofrece seguimiento de posición absoluta sin contacto y sin contacto, eliminando la necesidad de rutinas de homing adicionales o puntos de referencia. Esta característica, combinada con su alta resolución, garantiza mediciones precisas y detalladas, lo que los hace invaluables para aplicaciones críticas que requieren la máxima precisión.

Sensores insensibles

La ausencia de engranajes internos proporciona un funcionamiento verdaderamente sin contacto, y la tasa de protección IP69 evita la entrada no deseada de polvo, humedad o agua, lo que lo hace insensible a interferencias eléctricas y magnéticas.

Además de su funcionalidad, estos sensores cuentan con un diseño compacto e integrado que permite una integración perfecta en diversos sistemas y dispositivos. Su robustez y fiabilidad los hacen ideales para desplegar en entornos adversos, como configuraciones industriales o automotrices, donde la durabilidad es fundamental. Además, al eliminar la necesidad de componentes adicionales o procesos de calibración complejos, los sensores de posición de múltiples vueltas con encendido de energía real ofrecen una solución rentable para los requisitos de detección de posición.

En resumen, los sensores de posición de múltiples vueltas con encendido de energía real representan un avance significativo en la tecnología de detección de posición. Su capacidad para proporcionar mediciones precisas incluso después de interrupciones de energía, combinada con un consumo de energía nulo, capacidad de múltiples vueltas, seguimiento de posición absoluta, alta resolución y fiabilidad, los convierte en la opción preferida para una amplia gama de aplicaciones. Ya sea en automatización industrial, robótica, sistemas automotrices u otros campos, estos sensores ofrecen una precisión mejorada, eficiencia energética y ahorro de costos, transformando la forma en que abordamos la detección de posición.

- Capacidad real de encendido: Estos sensores proporcionan mediciones precisas de posición incluso después de interrupciones de energía o reinicios del sistema, eliminando la necesidad de recalibración o inicialización.

- Consumo de energía cero: Los sensores no requieren energía para mantener el seguimiento de la posición, lo que resulta en ahorros significativos de energía y permite aplicaciones alimentadas por batería.

- Capacidad de múltiples vueltas: Ofrecen seguimiento de posición a lo largo de múltiples revoluciones, lo que permite una medición precisa a lo largo de múltiplas rotaciones sin pérdida de precisión.

- Seguimiento de posición absoluta: Los sensores proporcionan información de posición absoluta, eliminando la necesidad de rutinas de homing adicionales o puntos de referencia.

- Alta resolución: Ofrecen una detección de posición de alta resolución, lo que permite mediciones precisas y detalladas para aplicaciones críticas.

- Diseño compacto e integrado: Los sensores tienen tamaños compactos y pueden integrarse en diversos sistemas y dispositivos, lo que los hace adecuados para aplicaciones con limitaciones de espacio.

- Robustos y confiables: Están diseñados para resistir entornos adversos y ofrecen confiabilidad a largo plazo, lo que los hace adecuados para aplicaciones industriales y automotrices.

- Rentables: Los sensores de posición de múltiples vueltas con encendido de energía real pueden generar ahorros al eliminar la necesidad de componentes adicionales o procesos de calibración complejos.

Aplicaciones de la vida real donde los sensores de posición de múltiples vueltas con encendido de energía real son comúnmente utilizados

- Automatización industrial: Estos sensores se utilizan ampliamente en sistemas de automatización industrial, como robótica, líneas de ensamblaje y máquinas CNC, para realizar un seguimiento preciso de la posición de las piezas móviles y permitir un control preciso.

- Sistemas Automotrices: Los sensores de posición de múltiples vueltas con encendido de energía real encuentran aplicaciones en sistemas automotrices, incluyendo el control del acelerador, medición del ángulo de dirección, sistemas de suspensión y seguimiento de la posición de la caja de cambios, asegurando un funcionamiento preciso y confiable.

- Energía Renovable: Se utilizan en turbinas eólicas y sistemas de seguimiento solar para monitorear la posición de las palas o paneles solares, optimizando la generación de energía y aumentando la eficiencia general.

- Equipos Médicos: Los sensores de posición de múltiples vueltas con encendido de energía real se emplean en dispositivos médicos como sistemas de cirugía robótica, sistemas de posicionamiento de pacientes y equipos de imagen médica para garantizar un posicionamiento preciso y control del movimiento.

- Aeroespacial y Aviación: Estos sensores desempeñan un papel crucial en aplicaciones aeroespaciales y de aviación, incluidos sistemas de control de vuelo, sistemas de navegación, control de motor y seguimiento de la posición del tren de aterrizaje, garantizando una operación precisa y segura.

- Embalaje y Manipulación de Materiales: Se utilizan en maquinaria de embalaje y sistemas de manipulación de materiales para rastrear la posición de cintas transportadoras, brazos robóticos y mecanismos de clasificación, lo que permite un control preciso y una operación eficiente.

- Maquinaria Agrícola: Los sensores de posición de múltiples vueltas con encendido de energía real se utilizan en equipos agrícolas como cosechadoras, pulverizadores y sistemas de riego, garantizando un posicionamiento y control precisos para mejorar la productividad.

- Construcción y Equipos Pesados: Estos sensores se utilizan en maquinaria de construcción como grúas, excavadoras y cargadoras para monitorear con precisión la posición y el movimiento del equipo, mejorando la seguridad y la eficiencia operativa.

- Aplicaciones Marítimas y Offshore: Se utilizan en sistemas marinos y offshore para el seguimiento de la posición de los componentes de los barcos, equipos de perforación offshore y sistemas de navegación marítima, garantizando un funcionamiento preciso en entornos desafiantes.

- Red Inteligente y Distribución de Energía: Los sensores de posición de múltiples vueltas con encendido de energía real se emplean en sistemas de redes inteligentes y redes de distribución de energía para monitorear la posición de interruptores, disyuntores y transformadores, lo que permite una gestión eficiente de la energía y la detección de fallos.