Application Note: Tractor Rear Hitch Position

Background

The rear hitch of a tractor is used to attach various implements such as plows, cultivators, sprayers, or trailers. A position sensor is needed to accurately detect and control the position of the hitch. The position information is then used by the tractor’s control system to regulate the hitch movement and ensure that the implement is properly aligned and functioning as desired. This improves the overall efficiency and effectiveness of the tractor’s operations and ensures that the attached tools are used safely and correctly.

Sensor requirements

The Hitch Draft Position Sensor must provide a reliable and accurate measurement of the hitch position, independent of the environmental conditions, such as shocks, vibrations, temperature changes and humidity.

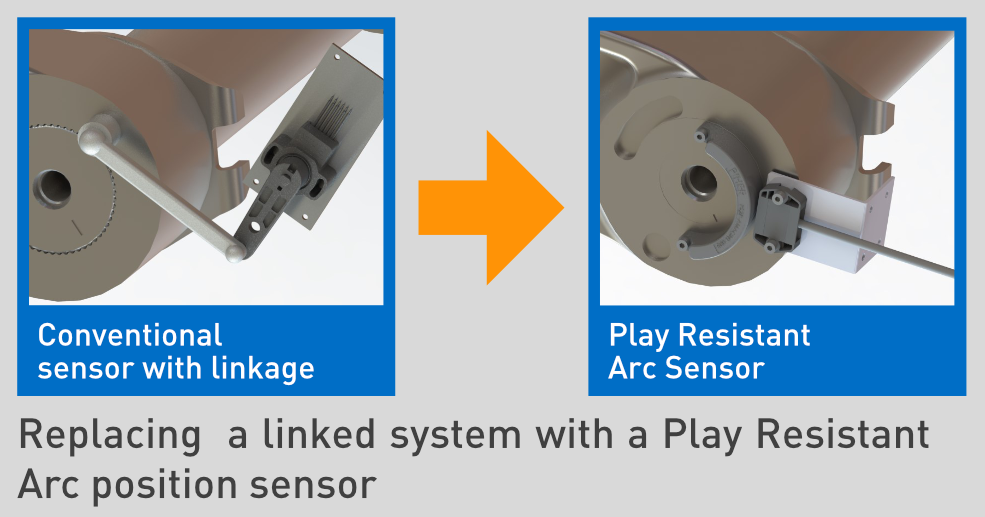

Drawbacks of linked sensor systems

Conventionally, the sensor is mechanically connected via arms or linkages to transmit the hitch’s movement to the sensors rotating shaft. This comes with several disadvantages:

- Mechanical errors and inaccuracies are introduced into the system and can negatively impact the performance and efficiency of the tractor’s operations.

- Vibrations, temperature changes and other environmental factors can cause additional accuracy errors.

- The mechanical linkage and the sensor are subject to wear and prone to failure. This can result in labor and cost intensive maintenance programs and tractor downtime.

- Installation and calibration of the sensor including the mechanical linkages result in a time and cost intensive assembly process.

PIHER solution

By using Piher Sensing System’s Play Resistant Arc Position Sensors the main pain points of linked sensor solutions are directly addressed:

- Play Resistant technology allows changes in air gap between the sensing element and the magnet. The sensor can move freely within a range of several millimeters, while maintaining the defined linearity error. This means that it is not affected by vibrations or changes due to mechanical tolerances of the tractor hitch.

- Complete touchless measurement means no mechanical errors and therefore inaccuracies are introduced into the system. Instead the movement is measured directly at the source.

- The sensor has virtually unlimited mechanical life, this means almost no maintenance is necessary and service downtime of the tractor can be avoided.

- Two separate sensor parts (the electronics and the arc magnet) allow simple installation and calibration and result in cost and time savings on the assembly line.

Learn More

Arc Position Sensors

The Play Resistant Arc Position Sensor is as available in a standard version. To find our more, visit:

Piher Sensing Systems provides a range of custom solutions to customers for agriculture, construction, material handling and marine applications. Other applications of Play Resistant Arc Position Sensors include solutions for skid steer bucket position, outboard steering, telehandler arm position.