Functional-Safety-Capable Sensor Platforms

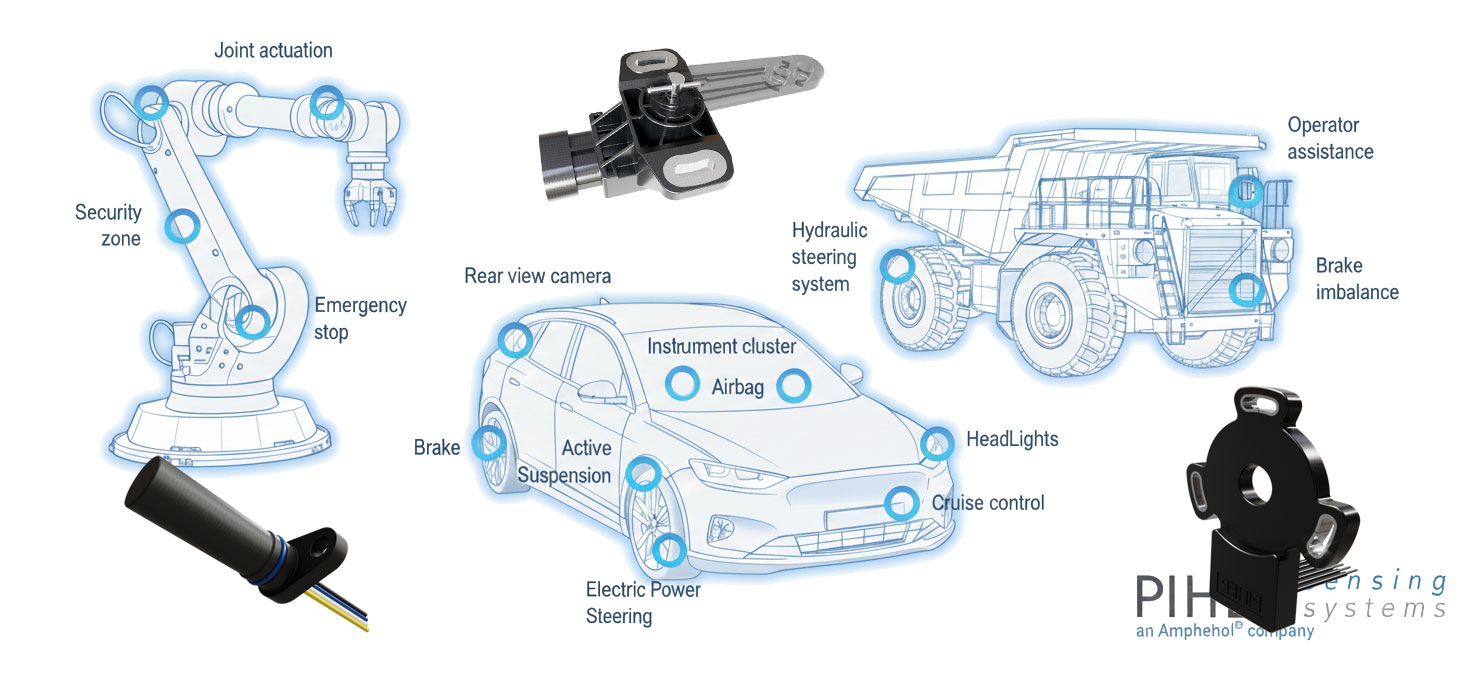

From e-mobility to off-highway and industrial automation, Piher Sensing Systems delivers rugged, configurable sensors and switches that support your path to functional safety — including inductive e-motor rotor position platforms designed for up to ASIL-D on sensor-level development, plus Hall position, tilt and gear-tooth speed families built for harsh duty.

ASIL Smart Position Sensors (ASIL C/D)

Smart position sensor platforms develope applications, with complete mechanical and electronic customization and architecture options for redundancy.

Typical applications

- Rotor position sensing for EV motors

- Steer-by-wire systems

- Active suspension systems

- Brake-by-wire and throttle-by-wire systems

- Rotary and linear sensing for transmission applications

Benefits for OEMs

- Complete mechanical and electronic customization

- Developed for safety-critical applications targeting ASIL C/D

- Patented multi-technology combination enabling redundant and full redundant sensor concepts

- Multiple communication protocol options, including CAN, SENT, and LIN

Functional Safety, Future Mobility

Functional safety is the absence of unreasonable risk due to hazards caused by malfunctioning behavior of electrical and electronic (E/E) systems. In practice, it means adding defined safety measures so that, even when faults occur, the remaining risk stays at an acceptable level.

Functional safety is different from intrinsic safety. Intrinsic safety removes the root cause of danger. Functional safety manages risk by combining robust design, diagnostics and safe system reactions, which is often the most practical and cost-efficient route for complex E/E systems.

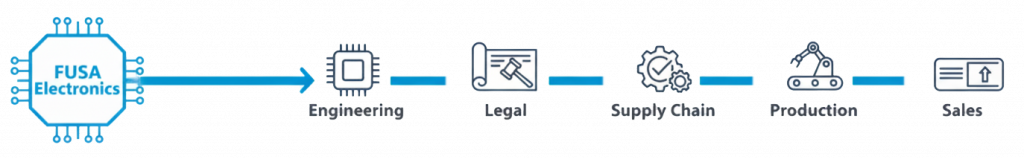

Why Choose Piher for Functional Safety Programs

ASIL-ready development pedigree

Capability to develop components with up to ASIL-D safety integrity support for critical systems such as braking and power steering. Smart position sensors are developed for safety-critical applications at the ASIL C/D level.

Stray-field immunity and true power-on position

Inductive magnet-free technology avoids magnetic stray-field influence and supports true power-on position, which is valuable near inverters and high-current conductors.

Rugged, wear-free sensing

High-accuracy, non-contact position sensing designed for harsh environments and long service life.

Redundancy and full-redundancy architectures

Multiple communication protocols available (CAN, SENT, LIN, etc.) to match system requirements and diagnostics strategies. Patented multi-technology combinations enable redundant and full redundant sensor approaches for safety concepts.

Customization of position sensors

Piher offers complete mechanical and electronic customization, providing both the development of entirely new custom solutions and the adaptation of existing designs into derivative products.

Global development close to you

Development and customized applications are carried out near the customer through our development centers located in Asia, Europe, and North America.

Talk to an engineer

Request a functional-safety design review

Share your application details and safety targets, and our engineers will recommend the best sensor platform, architecture, and documentation path.

Built for Your Standard and Market

Safety-Ready Sensor Capabilities

Free Functional-Safety Design Review

Map your ASIL, AgPL or PL targets to sensor architectures, diagnostics and interfaces. A short review with our team can help you select the right platform and de-risk your program early.

FAQs

ASIL (Automotive Safety Integrity Level) is determined during hazard analysis and risk assessment using severity, exposure and controllability. Importantly, ASIL is assigned to a safety function, not to a component. System-level architecture, diagnostics and validation are what allow an application to meet its ASIL target.

ASIL is achieved at the system level. Piher offers sensors, including inductive rotor position platforms designed for up to ASIL-D sensor-level development readiness, that help integrators reach their ASIL targets with appropriate diagnostics and architectures.

ISO 26262 is the automotive functional-safety standard for safety-related E/E systems. It defines lifecycle activities and work products from concept through production and operation. The standard focuses on hazards caused by malfunctioning behavior of safety-related E/E systems; other hazards are generally outside its scope unless they are directly triggered by such malfunctioning behavior.

They are different scales in different standards. Automotive uses ASIL A–D; off-highway uses AgPL a–e; industrial machinery uses PL a–e. Your required level is set by the risk assessment for each safety function (HARA for ISO 26262; PLr/AgPLr for ISO 13849/25119)

Yes. Several platforms offer redundant outputs, and products like TSDA are rated IP69K, while SSH-G01 speed sensors are IP67 sealed for transmissions and similar environments.

ASIL is achieved at the system level. Piher supplies sensors (notably our inductive e-motor rotor position platforms) that are designed so development according to ISO 26262 up to ASIL-D on the sensor level is possible. Integrators meet ASIL by architecture, diagnostics and validation.

Yes—our non-contact position, tilt and speed families are built for harsh mobile/industrial duty with IP67/IP69K options and CAN interfaces. These form solid building blocks for AgPL/PL targets; final compliance rests with the system

Automotive customers typically target ASIL B–D. Our inductive e-motor rotor sensors are ASIL-D-capable (sensor-level development) and are stray-field immune, ideal near inverters.

PSCI / PSTI inductive e-motor rotor sensors (true power-on, stray-field immune) and our Hall rotary/linear families (e.g., PSC-360, PS2P-LIN) with redundancy options. We can also support transmission speed/position sensing.

TSDA dual-axis tilt (IMU-based) for platform/boom leveling and Hall/inductive position sensors for pedals, hitches and steering, with IP69K variants and J1939 support.

Non-contact rotary/linear sensors plus gear-tooth speed for AGVs, conveyors, valves, etc. Our SSH-G01 speed sensor lists IP67/IP69K (ISO 20653) sealing and relevant EMC references

Share: target standard (ISO 26262/25119/13849), safety goal/target level (ASIL/AgPL/PL), environment (IP/temperature/EMC), mechanics (stroke/angle, mounting), interface (Analog/PWM/SPI/CAN), redundancy and supply details. Application is also desired (e.g., Brake System for EV, Hybrids and Conventional Cars, Automatic transmissions for passenger cars, Hybrid Dual-clutch automatic transmission (AT, CVT, DCT, ECVT), Shifting System for commercial vehicle transmissions)

We’ll suggest the best Piher platform and variant

Yes—engage us early. We’ll map sensor options (redundancy, interfaces, mounting) to your safety concept and point you to datasheets/app notes and contacts

Visit Support → Downloads for product guides, brochures, and application notes or alternatively ask to our digital assistant

Depending on platform and project needs, options include CAN, SENT, LIN, Analog, etc..