Why inductive motor control?

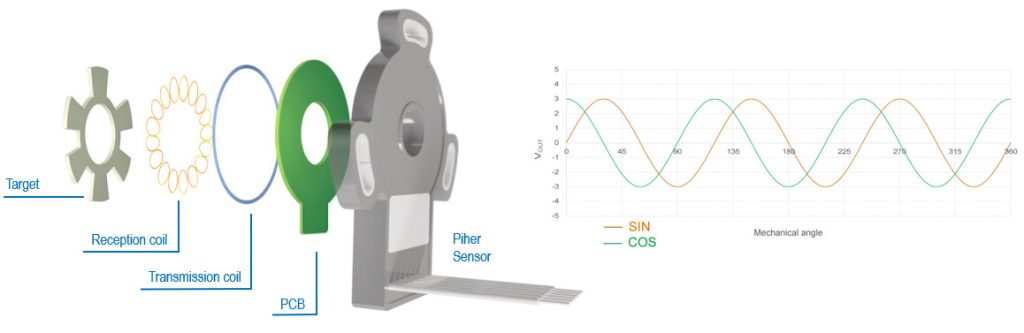

Working principle

Inductive position sensors use the physical principles of induction in a wire loop and eddy currents to detect the position of a conductive metallic target that is rotating above a set of printed copper coils consisting of one transmitter coil and two receiver coils. The possibility to perfectly customize the sensor to the motor dimensions enables more flexibility in the development of the electric / hybrid powertrain of the future.

Cost efficiency

Compared to conventional resolvers material costs can be significantly reduced as neither magnets, nor extensive copper windings or external components are needed and the overall number of parts is lower. Furthermore, the high robustness to misalignment and tilt enable further cost savings at the assembly line.

Design flexibility

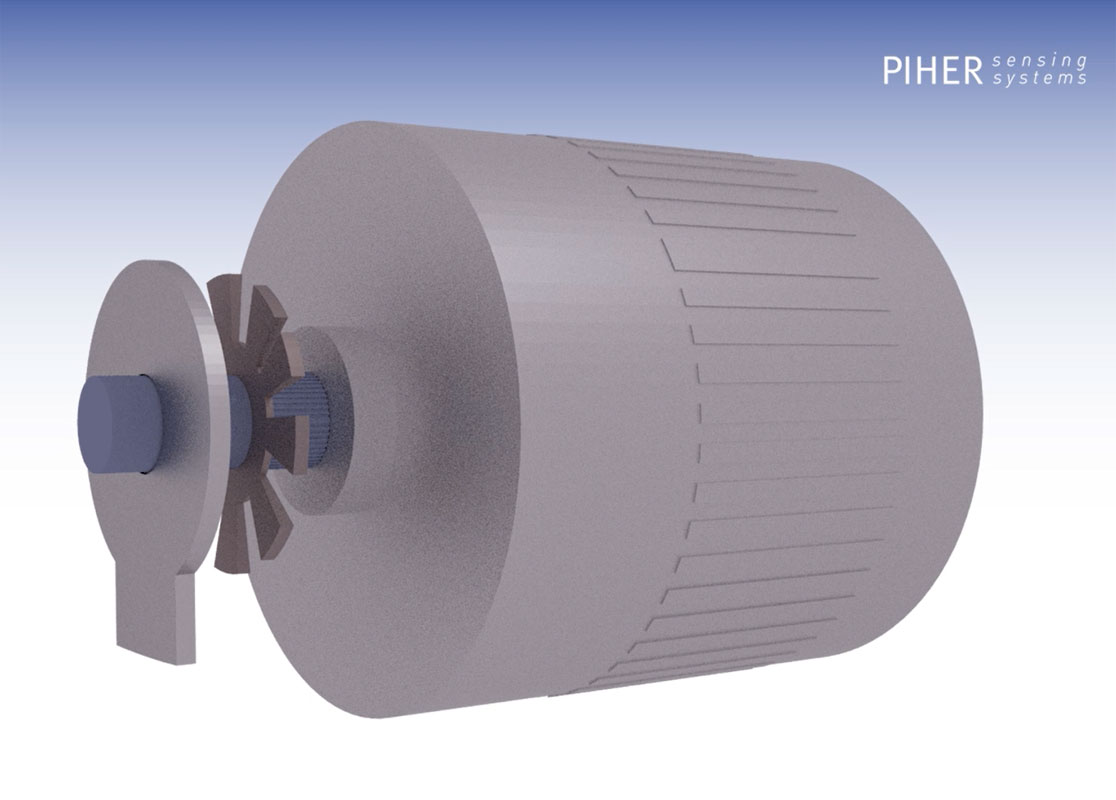

Completely adapted designs in through-shaft, on-shaft or arc configuration can be provided to OEMs by Piher Sensing Systems and are together with low power consumption, low weight and compact dimensions a further argument that speaks in favor of inductive technology. Support for safety-critical applications up to ASIL-D on sensor level can be reached through integration of an additional chip

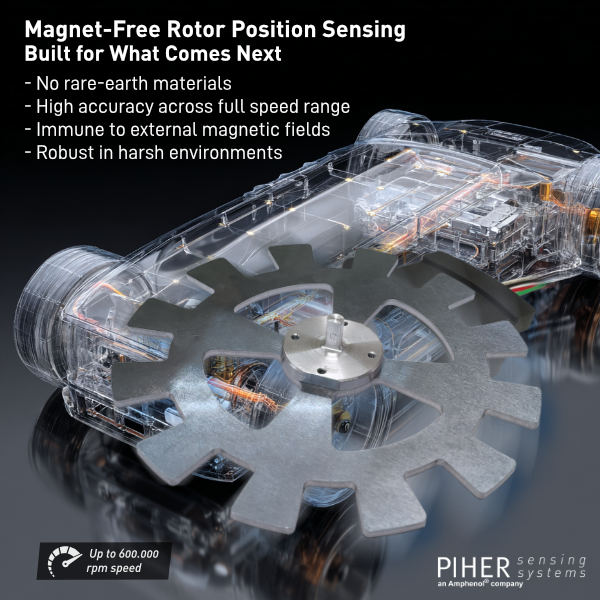

Reducing dependence on rare-earth materials is no longer a long-term ambition. It is a present engineering constraint.

At Piher, our inductive rotor position sensors are designed precisely for this shift. They deliver accurate, stable rotor position feedback for e-motor and powertrain applications, without using rare-earth magnets. The result is a sensing solution that is inherently resilient to supply chain volatility, magnetic interference, and harsh operating environments.

Thanks to magnet-less non-contact inductive technology, these sensors provide:

- Precise rotor position detection across the full speed range

- High immunity to external magnetic fields

- Robust performance under vibration, temperature extremes, and contamination

- A magnet-free architecture aligned with current automotive and industrial sourcing strategies

- Support for functional safety concepts, enabling system designs aligned with ISO 26262 requirements through predictable behavior, redundancy options, and stable signal integrity

- Up to 600.000 RPMs speed

Originally developed with electrified automotive powertrains in mind, Piher’s inductive rotor position sensors are also well suited for steer-by-wire, wheel steering, and demanding off-highway and agricultural machinery, where reliability and long-term stability are critical.

As OEMs and Tier-1 suppliers actively seek alternatives to rare-earth-based solutions, inductive sensing is moving from “alternative” to reference technology. Piher is proud to contribute practical, production-ready answers to this challenge

Inductive position sensors are non-contact magnetic sensors that are robust and able to withstand harsh environments, making them well suited for IIoT applications where consistent, high-quality information about device status and remote control is required.

In industrial IIoT and automotive contexts, anytime motion is measured there is an opportunity to use non-contact magnetic position sensors. Inductive sensors have a particular advantage in rejecting stray magnetic fields compared with other magnetic technologies.

Inductive position sensors generate a magnetic field using traces on PCB coils. A metallic target moving within the field induces eddy currents that alter the received signal. The difference in voltages from receive coils indicates the position.

These sensors can replace traditional resolvers on brushless motors, including electric vehicle traction motors. They offer lower cost and lower weight while maintaining robustness and can be used at high speeds.

Automotive-grade inductive position sensors can meet high temperature requirements and work reliably under harsh conditions.

Piher Sensing Systems’ Inductive Electric Motor Rotor Position Sensor offers a range of cutting-edge features that make it an ideal solution for modern electric motor applications. This sensor provides a cost-effective design, significantly reducing expenses when compared to traditional resolvers. It is designed with functional safety in mind, meeting ASIL-C and ASIL-D standards for critical automotive and industrial systems. The sensor is immune to stray magnetic fields without requiring additional shielding, ensuring reliable operation even in challenging environments. It is highly flexible, adaptable to various pole-pair e-motors, and supports customizable, lightweight packaging that suits specific application needs.The sensor’s contactless, magnet-free design enables seamless operation in harsh environments and extreme temperatures, while ensuring true power-on accuracy for precise motor positioning. It works with any electronically conductive material for eddy current generation, making it highly adaptable. Proven in HEV applications, it is robust against magnetic flux and stray fields while offering a lighter and smaller footprint compared to traditional resolvers. Additionally, it integrates easily with both end-of-shaft and through-shaft configurations, providing unmatched flexibility in system design.

Potential applications for Piher inductive position sensors

Automotive

Seat Position

Active suspension

Pedal Sensing

Throttle position

EGR control

Turbo valve

E-engine resolver replacement

Gear Shift

Steering

Steering angle

EPS motor rotor position

Gear position

Park inhibitor

Power brakes

Rotor position sensor

Off-Axis Rotor Position Sensing

Car Motor Commutation

Machine Positioning

Linear axis position

Rotary table position

Tool changer position

Motion Control

Servo motor rotor position

Actuator position feedback

Speed and direction Sensing

Industrial Motor Commutation

Hydraulics and Pneumatics

Valve position

Cylinder stroke position

Pump control

Process Control

Flow control valve position

Damper position

Mixer or agitator position

Energy and Power Systems

Generator rotor position

Wind turbine pitch control

Solar tracker position

Material Handling

Conveyor position

Lift and hoist position

Fork position

Industrial Safety

Emergency stop position monitoring

Guard and door position

Brake position monitoring

Robotics

Joint angle measurement

End-effector position

Gripper open/close position

For more information, visit the product page or contact us directly.